Quality Policy

We are committed to achieving customer satisfaction by supplying superior quality grade tubing and services that are delivered on time. We will accomplish this by continuing to improve our capabilities, complying with requirements, and maintaining the effectiveness of the quality management system.

Incoming Inspection

The raw material used at Optinova is always virgin material. Many of our materials have been previously approved as USP class VI or for food contact use and supporting documentation can be provided upon request. A certificate is always required from the raw material supplier. Incoming testing and inspection is performed according to each type of material and to our internal requirements.

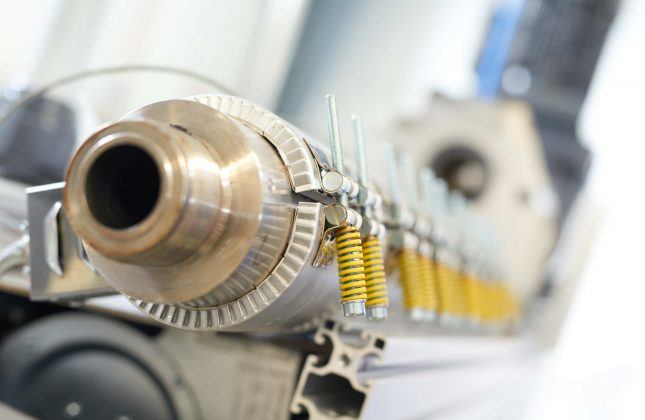

In-process Control

During start-up, samples are taken frequently and all the critical specifications of the tubing are reviewed. This also includes reviewing visual and tactile attributes that may impact the physical appearance of the tubing. When the extrusion process is stable and the tubing is within specifications, the production starts. The extrusion process is monitored throughout the entire production run by measuring the product for dimensional specifications including; OD, wall-thickness, ID, eccentricity and ovality. Additionally, all extrusion parameters are recorded in our process documentation, which is kept on file for a minimum of five years. All operators are responsible for the quality of each batch they produce and verify their work by taking samples and recording measurements randomly throughout the production run.

Final Inspection

All samples are taken randomly from each manufacturing batch. A test report with measurements from each batch and a CoC is included in each shipment, if required. We have full traceability on raw materials, process parameters and product control for each can, bag or spool of tubing. We are always open to discussion if our customers have special requirements.

Facility Quality Documents

Material Quality Documents

Product Quality Documents