Custom Precision Extrusion

At every step: quality (ISO), on-time delivery, automation solutions and partnership.

1. Prototyping

Quick-turn design. Hundred of materials. Toolbox - standard size samples.

2. Quality and design services

Custom precision extrusion. Scale up to production.

3. Design for manufacturing

Validation and verification. Product optimization. Custom production infrastructure

4. Large volume production

Process development. Automation handling. Alternative materials on production sites. Plant transfer services.

Design for you

Our Nordic roots mean that we are easy to work with, but uncompromising on quality. We listen to your needs and give honest feedback. Our experts can create innovative solutions to help meet your design needs: from polymer choices to information on tubing behaviour, lumen design, secondary operations and beyond. We are here to help you succeed.

Design services

Our design services are based on your needs. We keep design for manufacturing in mind, and are quality and compliance assured. With an Agile mindset, we provide design services in two different ways:

- Prototyping, co-creation of solutions in an iterative process or supply of sample kits

- Custom design projects, from idea or specification all the way to high-volume production

Competencies

- Polymer material knowledge, testing and analysis

- Extrusion processes and tooling design / manufacture

- Customized equipment, automation, robots, design engineering

- Quality and compliance management

- Agile development process

Secondary Operations

We offer secondary operations from manual prototyping to full scale production. Select from our existing capability portfolio, or work with us to design something unique for your project.

Get in touch with our global sales offices to learn more about our secondary operations and customizable solutions.

Welding

Etching

Flanging

Ring marking

Striped

PEBA-Braid-PEBA

Spiral forming

Flaring

Skiving

Tapering

Chamfering

Forming/Fabrication

Hole punching

Spiral cut

Extrusion Technology

We extrude a variety of fluoropolymers, thermoplastic polymers and thermoplastic elastomers, with various fillers, additives or compounds. Our wide range of extrusion lines include proprietary equipment designed and optimised by our in-house engineers. In-house expertise allows us to be agile in our approach to meet high quality standards, while helping you to achieve yours.

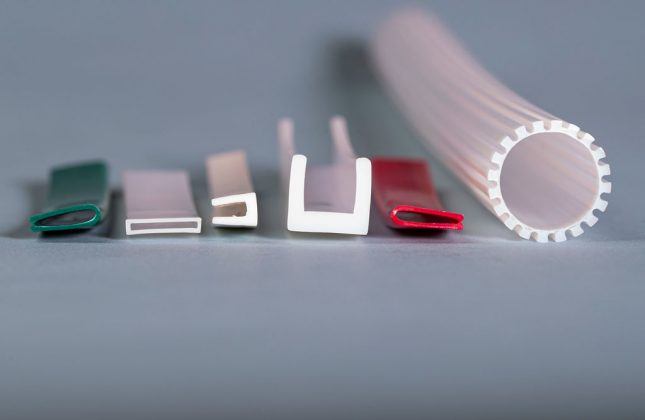

Monofilaments and Profiles

We can produce multi-purpose profiles for custom use across a wide variety of applications or mandrel as a stable inner core building block for high precision tubing. Size ranges from 0.3 mm.

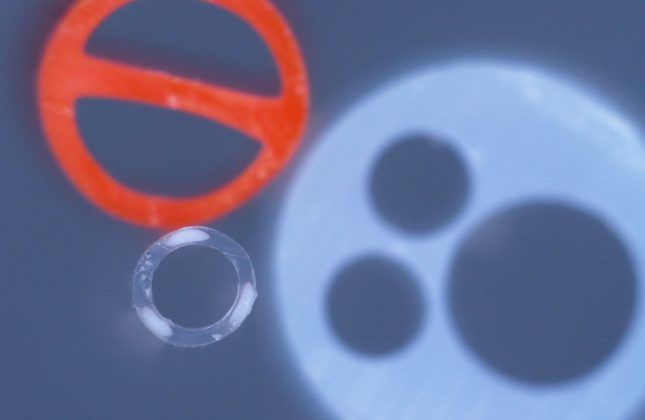

Single- and multi-lumen extrusions

Various polymers extruded into single- or multi-lumen cut to length or spooled. Size ranges from 0.3 mm. Tolerances are down to less than 1% of dimensions. We can extrude over 20 lumens. We offer the following special tubing types:

- Etched OD PTFE Liners with ultra thin-walled lubricious inner layer

- PTFE and FEP Heat Shrink

Co-extrusions and multi-layered solutions

In order to combine various properties in the same tube we can extrude polymers in different layers; for example, a stiff inner layer for torque momentum and kink resistance and a soft outer layer for patient comfort. Stripes extruded in the walls for aesthetic appearance, x-ray visibility or similar functionality can also easily be added.

Polymer Engineering

With extensive knowledge of polymers and extrusion, our polymer engineers are available to help you make the right choice for your Optinova extrusion project. We offer extensive raw material and tube analysis services as part of any design project. Working closely with Optinova’s process experts ensures that our polymer engineers truly understand how the raw material properties are affected by the extrusion process, and the effects that this has on the tubing.

World of Polymers

We work with a wide variety of polymers to produce tubing solutions. Our compounding technology is unparalleled in the industry. Our material product portfolio includes, but is not limited to:

- Thermoplastic Fluoropolymers: PTFE, FEP, PFA, ETFE, PVDF, etc.

- Polyolefins: LDPE, HDPE, PP, etc.

- Thermoplastic Elastomers: TPE-U, TPE-A, TPE-S, etc.

- Other thermoplastics: PA11, PA12, POM, PC, etc.

Compounds, fillers and additives

By adding compounding fillers, additives or colorants to a polymer you can alter its properties, allowing you to achieve the right color, have radiopacity, lubrication, antistatic properties, conductivity and more. For the highest possible quality, we compound selected materials in-house.