Knowing the thermal properties of a polymer and its thermal transitions is imperative to determine the most suitable product application for the polymer. In the two previous articles, we have explored the fundamental differences between polymers and briefly mentioned amorphous and crystalline plastic. We have also discussed that each polymer has a unique glass transition and melting temperature. When one applies heat on a polymer, one launches its thermal transition process which ultimately alters the attributes of the polymers in its current state. In this article, we will explain in the simplest way the two most typical thermal transitions in polymer, one driven by the polymer’s glass transition temperature, and the other by its melting temperature.

Tech Story

Issue 3 (September 2021)

Sonja Granith, Polymer Engineer, Optinova Innovation Center

The thermoplastics that we work with are either amorphous or crystalline polymers. And it is worth noting that almost no polymer is 100% crystalline, i.e. every polymer has a varying composition of both amorphous and crystalline qualities. However, most polymers are approximately 10-30% crystalline, thus there is always a part of the plastic to be in amorphous state (1).

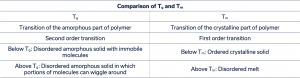

While the glass transition temperature (Tg) of a polymer is a property of its amorphous region, the melting temperature (Tm) is a property of the polymer’s crystalline region. This also means that 100% amorphous polymers would have no Tm and hypothetically, there would be no Tg for 100% crystalline polymers.

When a polymer exists below its Tg, it will be in a glassy state. And the same polymer would be in a rubbery state if it is heated above its Tg (2). While polymers such as PS and PMMA are often used in their glassy state, i.e. below their Tg, to achieve hard and brittle qualities, other polymers are heated above their Tg to achieve a rubbery state. An example of a polymer used in a rubbery state, above their Tg, is natural rubber which is a soft and flexible polymer (3).

At melting point, the crystalline structure of the polymer is melted and thus gets disordered and highly viscous. In thermodynamics, these thermal transitions can be explained as first and second order transitions. Melting point is a first order transition and glass transition is second order (1).

Figure 1: Comparison of glass transition temperature (Tg) and melting point (Tm)

Hopefully, you have now partially understood why a polymer’s thermal properties are vital indicators of what product applications and environmental conditions that the polymer will perform best. In the next articles, we will go further into the details of each polymer that we work with here at Optinova. Stay tuned!

Source:

(1) K. Balani, V. Verma, A. Agarwal and R. Narayan. 2015. Biosurfaces: A Materials Science and Engineering Perspective. John Wiley & Sons, Inc, New Jersey.

(2) C. Harper and E. Petrie. 2003. Plastic materials and processes. A concise encyclopedia. John Wiley & Sons, Inc, New Jersey.

(3) Omnexus spechialchem. Link: https://omnexus.specialchem.com/polymer-properties/properties/glass-transition-temperature#melting. Accessed August 2021.

(4) Thermal properties of polymers. Link: https://www.onlinestudybook.com/thermal-properties-of-polymers/. Accessed August 2021.

In order to provide customers with comprehensive tubing solutions, we engage in an open and transparent dialogue with them – that’s the Optinova way. We bring to the table 50 years of expertise in polymers, extrusion automation, secondary operations and quality management.

Andreas Perjus, CTO, Optinova Group

Technology

We take pride in being the top-of-mind thermoplastics and fluoropolymers extrusion partner of over 1 000 customers ever since 1971.

Medical Tubing

From IV tubing to medical-grade heat shrink, we provide customers with the broadest, most versatile tubing solutions for different medical applications.

Industrial Tubing

Optinova offers the most customizable PTFE, FEP, PFA, ETFE, PVdF, MFA and PEEK tubing, available in virtually any size and profile, with deliveries available across the globe.