Monomer is the base unit of polymer. The word polymer simply refers to large molecules whose structure is composed of multiple monomers (1). It is worth noting that all plastics are polymers, however there are polymers that are not plastics, such as DNA and protein. In this article, we will focus on defining the different types of plastics and explaining what we produce here at Optinova.

Tech Story

Issue 1 (July 2021)

Sonja Granith, Polymer Engineer, Optinova Innovation Center

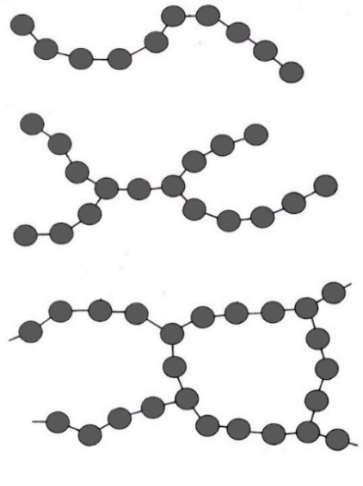

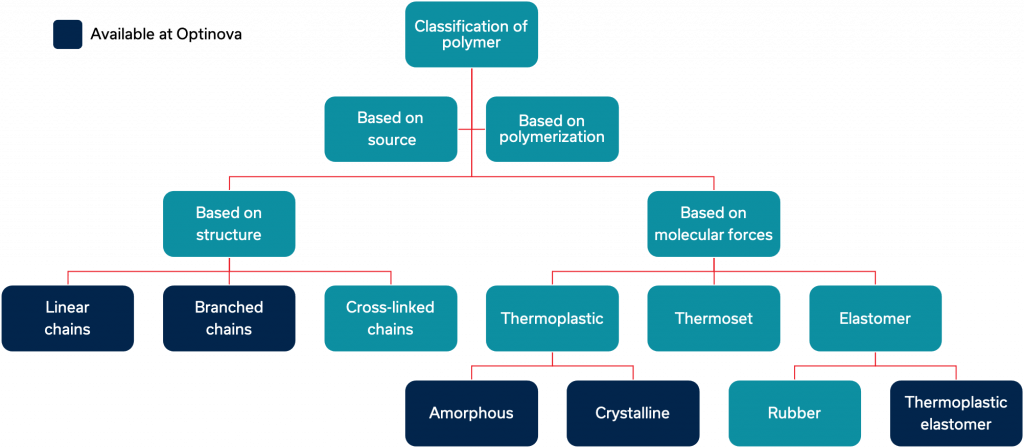

There are several ways to divide polymers into different groups. However, the most common method is to divide them by structure. There are linear, branched and cross-linked chains (see Figure 1). During the process of polymerization, the basic units, monomers, are put together to form polymers. In this process, monomers can build a long, linear chain. The chain can also be branched or cross-linked. These polymers are thermosetting, meaning that they are produced by permanently hardening a soft solid or liquid resin. In these plastics, the polymer chains are connected, and they form a three-dimensional network. This cross-linking reaction is irreversible, i.e. one cannot melt thermosetting polymer (1) (2). Both linear and branched structures belong to the thermoplastic group, and we produce these at Optinova.

Figure 1: Linear, branched, cross-linked polymer structures

Thermoplastic can be further divided into amorphous and crystalline polymers. Most of the raw materials we use are crystalline, but we do have a few amorphous polymers in our portfolio.

Apart from thermoplastic and thermoset, there is a third group of plastic called elastomer. As the name suggests, elastomer is a group of elastic polymers and many of them have rubber-like properties. This group can be further divided in two, rubber and thermoplastic elastomer. Thermoplastic elastomers have both elastic properties as rubber and structures like thermoplastics (1) (2). We do not work with rubbers at Optinova, but we have 50 years of experience with thermoplastic elastomers (see Figure 2).

Figure 2: Optinova’s world of polymers

This article is a brief introduction into the world of polymers and the materials that we produce here at Optinova. We hope that you have now understood the difference between polymer and plastic and can distinguish the different groups of polymers and their unique properties. In the next articles of the series, we will take time to explore each polymer group more in detail. Stay tuned!

Source:

(1) C. Harper and E. Petrie. 2003. Plastic materials and processes. A concise encyclopedia. John Wiley & Sons, Inc, New Jersey.

(2) C. Jr. Carraher. 2003. Seymour/Carraher’s Polymer Chemistry, Sixth Edition. Marcel Dekker, Inc., New York.

In order to provide customers with comprehensive tubing solutions, we engage in an open and transparent dialogue with them – that’s the Optinova way. We bring to the table 50 years of expertise in polymers, extrusion automation, secondary operations and quality management.

Andreas Perjus, CTO, Optinova Group

Technology

We take pride in being the top-of-mind thermoplastics and fluoropolymers extrusion partner of over 1 000 customers ever since 1971.

Medical Tubing

From IV tubing to medical-grade heat shrink, we provide customers with the broadest, most versatile tubing solutions for different medical applications.

Industrial Tubing

Optinova offers the most customizable PTFE, FEP, PFA, ETFE, PVdF, MFA and PEEK tubing, available in virtually any size and profile, with deliveries available across the globe.